In the intricate world of hydraulic systems, precision and efficiency reign supreme. Among the many tasks that ensure these systems operate at peak performance, bleeding double-acting hydraulic cylinders stands out as both a critical and frequently enough underestimated art. Whether you’re a seasoned technician or a curious enthusiast, mastering this process can be the difference between a smoothly functioning machine and one plagued by inefficiency or failure.But what does it truly take to bleed a double-acting hydraulic cylinder effectively? This article delves into the nuances of the process, offering insights, tips, and step-by-step guidance to help you navigate this essential skill with confidence. From understanding the fundamentals to troubleshooting common pitfalls, we’ll equip you with the knowledge to elevate your hydraulic expertise. Let’s unlock the secrets to seamless cylinder performance and keep your systems running like a well-oiled machine—literally.

Understanding the Mechanics of Double Acting Hydraulic Cylinders

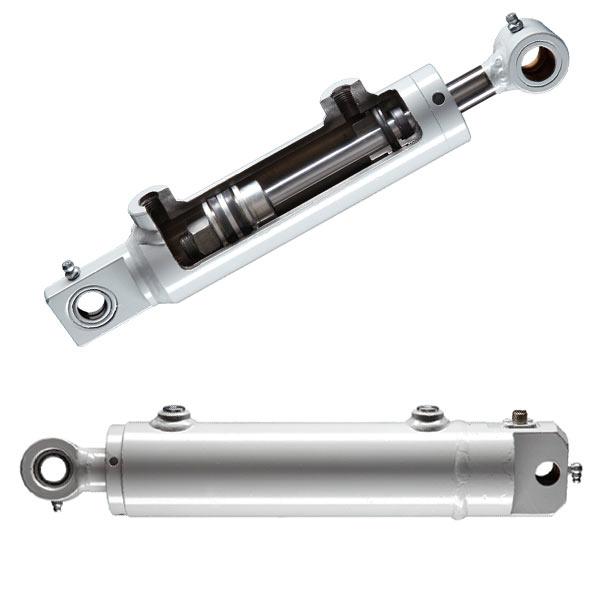

Double acting hydraulic cylinders are the powerhouse behind countless industrial applications,offering precise control and reliable force in both extension and retraction strokes. Unlike their single-acting counterparts, these cylinders utilize hydraulic fluid on both sides of the piston, enabling smoother operation and higher efficiency. Key components of a double acting cylinder include:

- piston Rod: Transmits force to the load.

- Seals: Prevent fluid leakage and maintain pressure.

- Ports: Allow hydraulic fluid to enter and exit the cylinder.

- Cylinder Barrel: Houses the piston and fluid.

Bleeding air from these cylinders is crucial for optimal performance, as trapped air can cause spongy movements, reduced efficiency, or even damage. Follow these steps to ensure a proper bleed:

| Step 1 | Extend the cylinder fully to push air toward the ports. |

| Step 2 | Loosen the hydraulic line slightly to release trapped air. |

| Step 3 | Retract the cylinder slowly, allowing fluid to purge remaining air. |

Step-by-Step Guide to Properly Bleeding Hydraulic systems

Bleeding double-acting hydraulic cylinders is essential for maintaining optimal performance and preventing air pockets that can lead to system failure. Follow these steps to ensure a smooth and efficient process:

- Prepare the system: Turn off the hydraulic power and relieve any residual pressure by moving the control lever back and forth.

- Locate bleed valves: Identify the bleed ports on the cylinder—typically found near the piston rod or cylinder ends.

- Open the valves: Use a wrench to loosen the bleed screws slightly, allowing trapped air to escape.

- Cycle the cylinder: Actuate the cylinder slowly, pushing fluid through the system until no air bubbles are visible in the expelled fluid.

For best results, monitor fluid levels and top off the reservoir as needed to avoid introducing more air into the system. Consistency is key—repeat the process if bubbles persist. Below is a quick reference for common issues and solutions:

| Issue | Solution |

|---|---|

| Persistent air bubbles | Check for leaks or insufficient fluid levels |

| Weak cylinder movement | Re-bleed and inspect for internal damage |

| Fluid contamination | Replace hydraulic fluid and clean the system |

essential Tools and Safety Precautions for Effective Bleeding

Bleeding double-acting hydraulic cylinders requires precision and the right tools to ensure optimal performance and safety. Essential tools include a high-quality hydraulic jack or pump, clear vinyl tubing to monitor fluid flow, and a wrench set for secure fittings. Don’t forget a clean, lint-free cloth to wipe spills and a funnel for smooth fluid transfer. Safety is paramount—always wear protective gloves and goggles to shield against high-pressure fluid leaks.work in a well-ventilated area and keep a fire extinguisher nearby, as hydraulic fluid is flammable.

| Tool | Purpose |

| Hydraulic Jack | Generates pressure for bleeding |

| Clear Tubing | Visualizes air bubbles |

| Wrench Set | Secures fittings during the process |

Before starting, inspect all components for wear or damage—cracked hoses or loose fittings can lead to perilous failures. Always follow the manufacturer’s guidelines for fluid type and bleeding sequence. key precautions include relieving system pressure first and never over-tightening connections, which can strip threads. Keep bystanders at a safe distance and double-check that the cylinder is stable to prevent accidental movement. A methodical approach minimizes risks and ensures a flawless bleed every time.

Troubleshooting Common Issues During the Bleeding Process

Bleeding double-acting hydraulic cylinders can sometimes be challenging, especially when unexpected issues arise. One common problem is airlock formation, which prevents proper fluid flow. To resolve this, ensure the cylinder is positioned correctly and slowly cycle the piston multiple times to expel trapped air. Another frequent issue is fluid leakage, often caused by worn seals or loose fittings. Inspect the cylinder for visible damage and tighten connections securely. For stubborn air pockets, consider using a vacuum pump to remove air efficiently.

Below is a quick reference table to address common problems:

| Issue | Solution |

|---|---|

| Incomplete bleeding | Cycle the piston repeatedly and check fluid levels |

| Unusual noises | recheck for air pockets or contamination |

| Fluid contamination | Replace hydraulic fluid and clean the system |

Additionally, here are some tips to streamline the process:

- Use clean hydraulic fluid to prevent contamination and ensure smooth operation.

- Check for external damage like dents or scratches that might affect performance.

- Monitor pressure levels to avoid overloading the cylinder during bleeding.

Maintaining Optimal Performance After Bleeding Double Acting Cylinders

Once you’ve successfully bled your double-acting hydraulic cylinders, maintaining their optimal performance is crucial to ensure longevity and efficiency.regular inspection and maintenance are key to preventing air ingress and fluid contamination,which can compromise performance. Here are some essential practices to follow:

- Monitor Hydraulic Fluid Levels: Check fluid levels periodically and top up with the recommended hydraulic fluid to avoid air bubbles.

- Inspect Seals and Connections: Regularly examine seals, hoses, and fittings for wear or leaks that could allow air into the system.

- Maintain Cleanliness: Keep the hydraulic system clean to prevent contaminants from entering the fluid, which can cause blockages or damage.

Additionally, understanding the system’s operating conditions and adhering to manufacturer guidelines will help you avoid common issues. Below is a quick reference table to help you keep track of maintenance tasks:

| Task | Frequency |

|---|---|

| Check fluid levels | weekly |

| Inspect seals & connections | Monthly |

| System cleanliness check | Bi-weekly |

Wrapping up

So, there you have it—your blueprint to mastering the art of bleeding double-acting hydraulic cylinders. Think of it as a dance between precision and patience,where every step ensures smoother,more reliable performance. With these techniques in your toolkit, you’re not just maintaining machinery; you’re fine-tuning a symphony of motion and power. Remember, hydraulic systems thrive on care, and a well-bled cylinder is the heartbeat of seamless operation. Whether you’re a seasoned pro or a curious newcomer, take pride in this skill—it’s the kind of expertise that keeps the gears of industry turning. Now, go forth and make those cylinders purr—because in the world of hydraulics, perfection is always just a bleed away.